Turbo Manifold Reverse Engineering

Cory Misko, the talented fabricator behind Fresh Produce Manufacturing, came to me with the project of taking an already existing turbo manifold and turning it into a production ready piece using off the shelf flanges and sch10 stainless steel pipe.

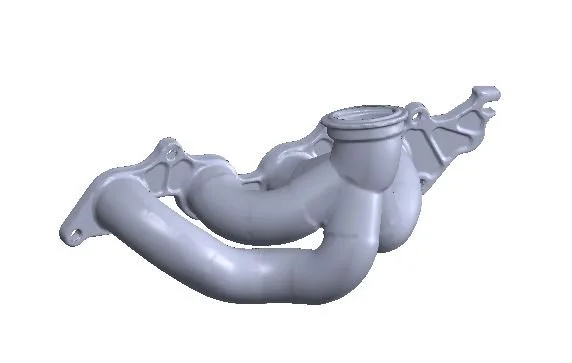

To start this process, the manifold was shipped to me and 3D scanned. Once scanned, the manifold was sent back to Cory and used to design manufacturing jigs while being reverse engineered.

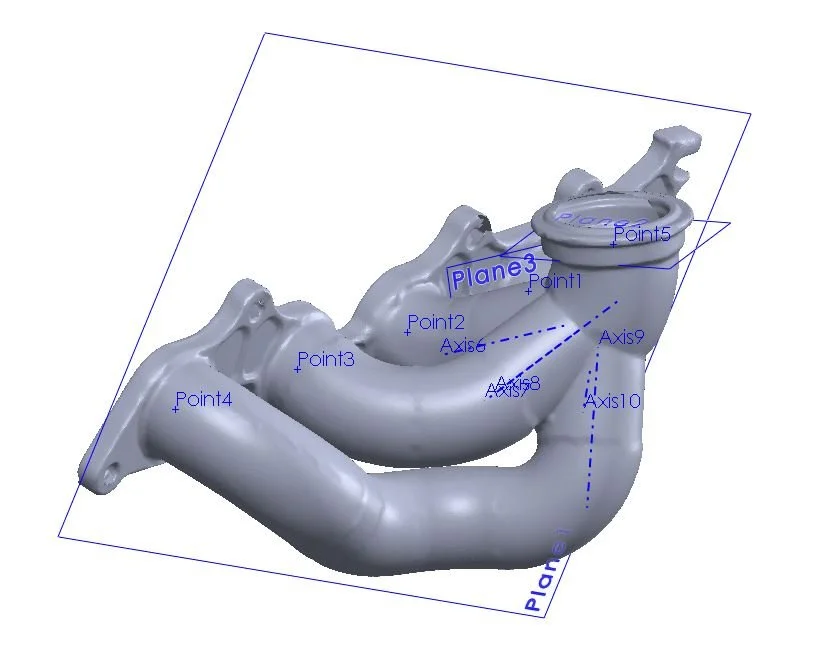

Once the scan was processed, I extracted important geometry such as the turbo location, cylinder head flange location, individual cylinder head runner locations, and collector angle. These pieces of information are critical to replicating the manifold geometry.

With this data, I began rebuilding the manifold starting at the most important areas.

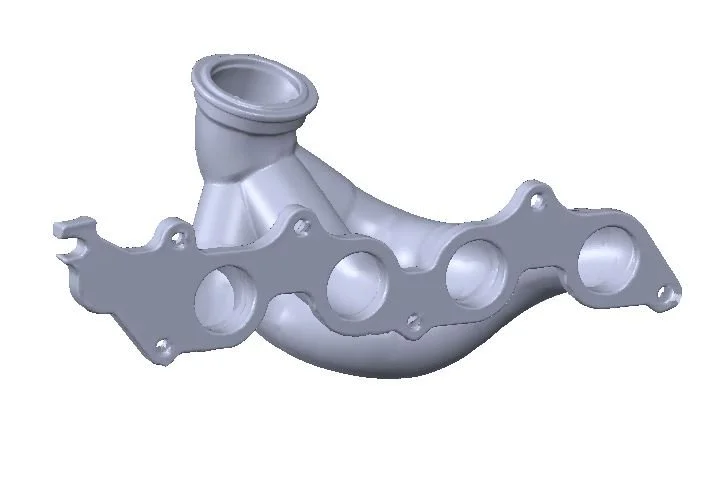

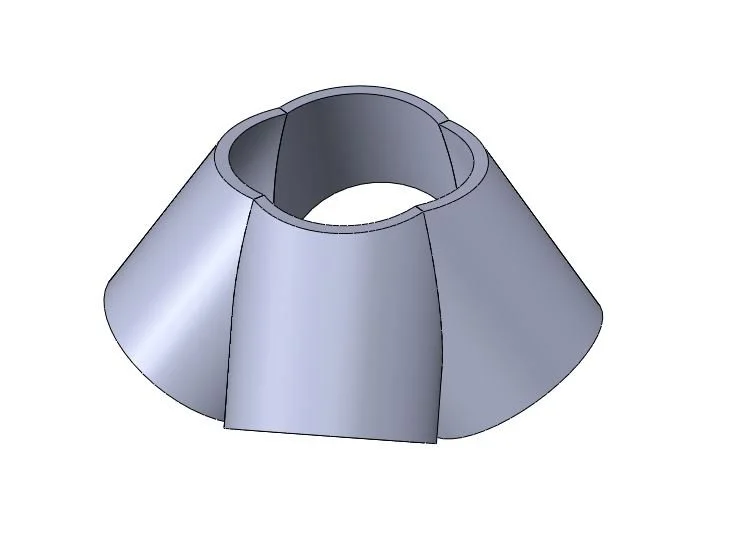

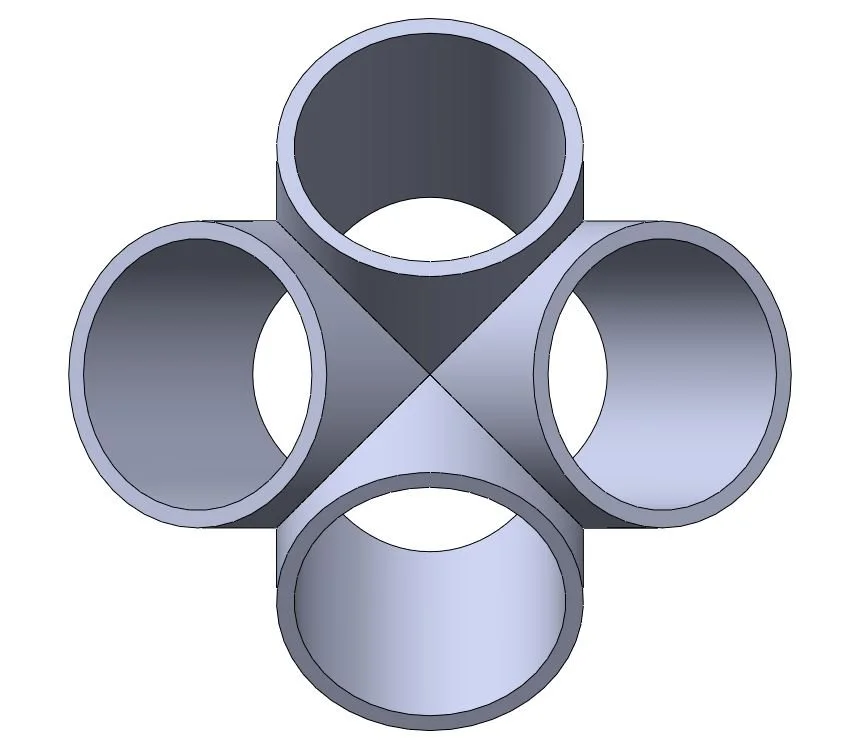

The collector is the first item that needs to be designed and located as it will drive all of the runner geometry. Being a four cylinder, this is a fairly simple collector with all identical runners and a cast elbow added on top.

Once the design was finalized, to make things simple, the runner files were exported and laser cut by Precision Tube Laser in Las Vegas.

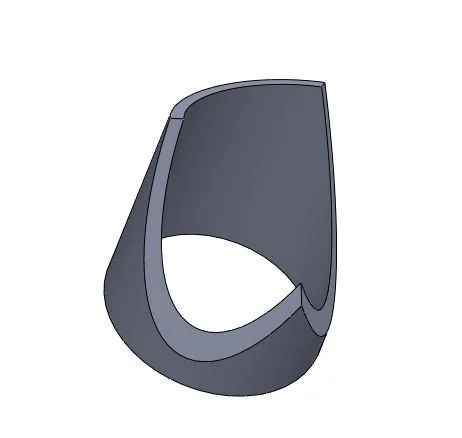

Lastly, a jig is designed and 3D printed to locate the rotation of the elbow that is placed on top of the collector.

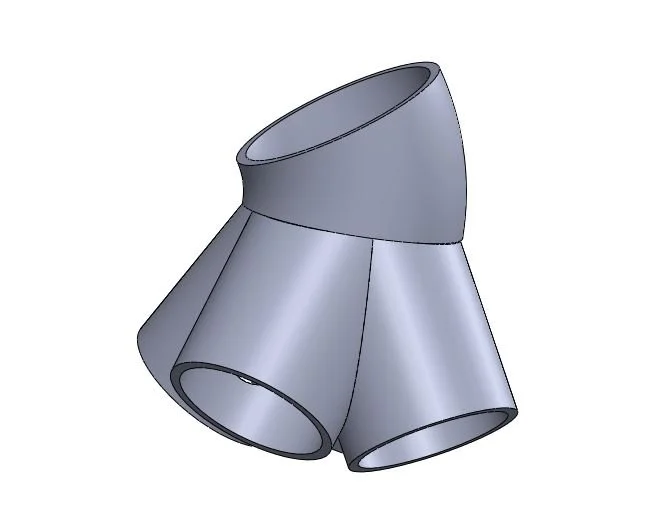

With the collector location and design complete, the next critical part is the shortest runner.

This runner consists of two elbows and a very small straight section, which does not allow for very much error. If this runner is not mocked up first, there is a very good change the design will have to be adjusted to fit correctly. Once fitted the remaining three runners can be fitted.

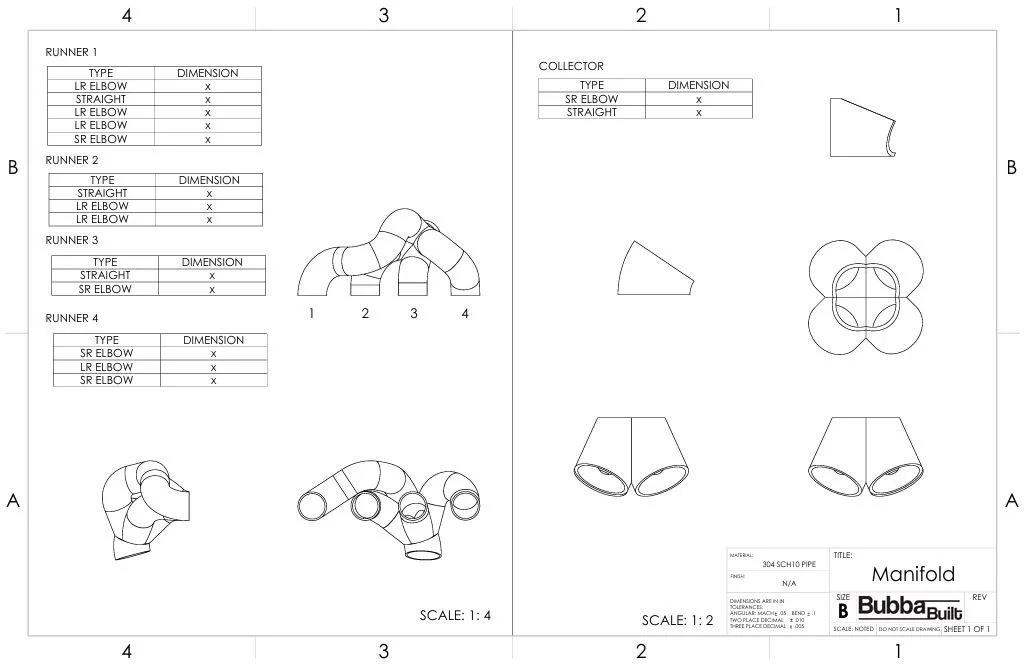

With all of the runners complete, a detailed drawing with dimensions of each component was created.

This drawing makes the fabrication extremely straight forward and easy to reference.